FAQ

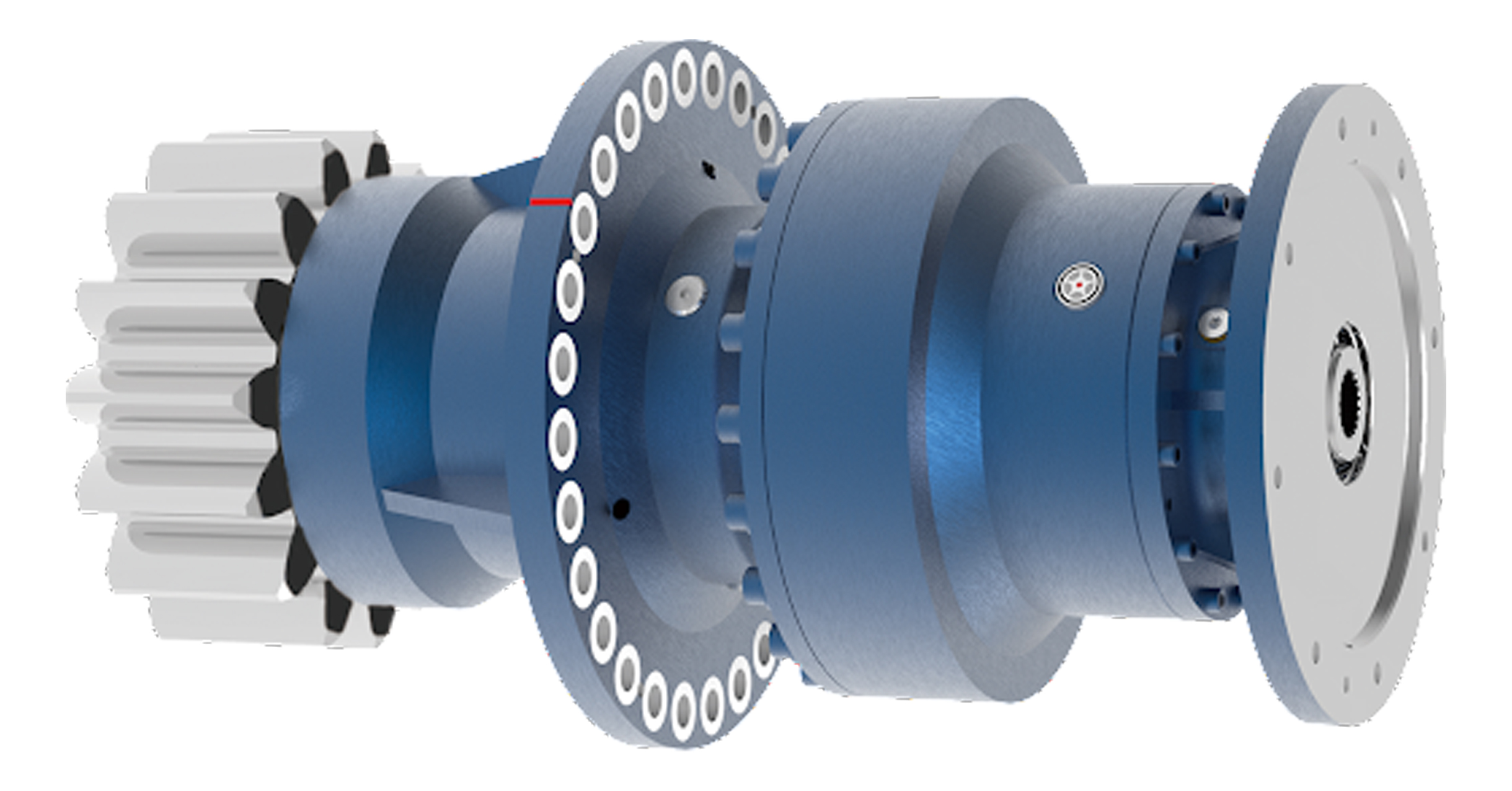

Yaw Planetary Gear Drive System

The Yaw Gear drive is an important component of the horizontal axis wind turbines' yaw system. To ensure the wind turbine is producing the maximal amount of electric energy at all times, the yaw drive is used to keep the rotor facing into the wind as the wind direction changes. This only applies for wind turbines with a horizontal axis rotor. The wind turbine is said to have a yaw error if the rotor is not aligned to the wind. A yaw error implies that a lower share of the energy in the wind will be running through the rotor area.

The Year drive gearbox of the yaw drive is a very crucial component since it is required to handle very large moments while requiring the minimal amount of maintenance and perform reliably for the whole life-span of the wind turbine. Most of the yaw drive gearboxes have input to output reduction ratios in the range of 1:1200 ~ 1:2000 in order to produce the enormous turning moments required for the rotation of the wind turbine nacelle. Varitron yaw gear drive system uses high efficienct planetary gear train, Several spur gears distributed evenly around the circumference run between a gear with internal teeth and a gear with external teeth on a concentric orbit.

The advantages of using planetary gear in Yaw Drive:

-Coaxial arrangement of input shaft and output shaft, to fit compact space in wind turbine nacelle.

-Load distribution to several planetary gears

-High efficiency yaw drive due to low rolling power

-Large unlimited transmission ratio options due to combination of several planet stages

-Possibility of use as overriding gearbox

-Favorable pitch gear output use in wind turbine system

Address:No.45, Lane 171, Chung Shin Road, Wuku District, New Taipei City, Taiwan

Tel:+886-2-29889598

Fax:+886-2-29850998

Email:[email protected]

Copyright 2014 © Varitron Engineering (Taiwan) Co., Ltd. All Rights Reserved.